Introduction

Bitumen is the unsung hero of modern infrastructure. It binds our roads, holds our airport runways together, and plays a vital role in waterproofing buildings. Without it, development would literally come to a halt. As Malaysia pushes forward with its infrastructure development goals in 2025, the cost of bitumen becomes more than just a price point—it becomes a national economic indicator.

So, what’s happening with bitumen prices in Malaysia in 2025? Are they stable, rising, or fluctuating like a roller coaster? If you’re a contractor, developer, supplier, or even an investor, keeping your eye on these figures is crucial. The price of bitumen affects everything from tender costs to final project profitability.

This guide dives deep into the bitumen price landscape in Malaysia in 2025. We’ll cover what’s driving the market, where it’s heading, and how you can navigate it smartly. Whether you’re planning a highway, managing logistics, or just want to understand the market better—this one’s for you.

What is Bitumen?

Bitumen is a black, sticky, semi-solid form of petroleum. It’s often confused with asphalt, but let’s clear that up first: bitumen is the binding material, while asphalt is the mix of bitumen with aggregates like sand, gravel, or crushed stone.

In Malaysia, bitumen is primarily used for:

- Road construction and maintenance

- Roofing and waterproofing

- Industrial applications like pipeline coatings

- Airport runway surfacing

It’s versatile, durable, and crucial for long-lasting infrastructure. The Malaysian climate, with its high rainfall and tropical heat, makes high-quality bitumen a necessity—not a luxury.

There are several grades of bitumen based on its penetration value, viscosity, and performance under heat. In tropical climates like Malaysia’s, modified and high-performance grades are in high demand to resist rutting, cracking, and water damage.

As Malaysia expands its infrastructure footprint under initiatives like the Twelfth Malaysia Plan (12MP), demand for bitumen continues to surge. Naturally, price fluctuations follow this demand closely, making bitumen a hot topic in the construction and energy sectors.

Current Bitumen Prices in Malaysia (2025)

As of Q4 2025, the average price of bitumen in Malaysia hovers between RM1,850 to RM2,300 per metric tonne, depending on grade, origin, and supplier. For locally manufactured penetration grade 60/70, prices are typically at the lower end, while polymer-modified variants (PMBs) and imported bitumen from the Middle East and India command a premium.

Several real-time factors influence the pricing:

- Crude Oil Prices: Bitumen is a byproduct of crude oil. In 2025, Brent crude remains volatile, averaging around USD 87 per barrel, which directly impacts bitumen prices.

- Logistics Costs: Malaysia’s ports and highways are essential for bitumen distribution. Any hike in transportation or port handling charges affects the end price.

- Currency Fluctuations: As most bitumen imports are priced in USD, the RM-USD exchange rate plays a crucial role.

- Demand-Supply Gaps: With increasing demand and limited refinery output, prices tend to rise. Seasonal demand during monsoon or mega-project launches can lead to sudden spikes.

For buyers and planners, it’s critical to work with reliable suppliers who offer price locks or contracts to protect against unexpected price hikes.

Historical Trends in Bitumen Prices (2015–2024)

Understanding the past helps predict the future. Let’s take a quick journey through bitumen prices over the last decade in Malaysia:

| Year | Avg Bitumen Price (RM/MT) | Major Influences |

|---|---|---|

| 2015 | RM1,450 | Stable crude prices |

| 2016 | RM1,350 | Global oil price dip |

| 2017 | RM1,600 | Demand growth |

| 2018 | RM1,800 | Oil price hike, GST impact |

| 2019 | RM1,750 | Infrastructure funding cuts |

| 2020 | RM1,500 | COVID-19 disruptions |

| 2021 | RM1,700 | Recovery phase, rising oil |

| 2022 | RM2,100 | Global oil crisis, Ukraine war |

| 2023 | RM1,950 | Stabilization post-Ukraine shock |

| 2024 | RM2,200 | Budget 2024 infrastructure focus |

Each fluctuation tells a story. From global oil price collapses to pandemic-related supply shocks, Malaysia’s bitumen pricing history is closely tied to both global events and local policy decisions.

Looking at this trend, 2025 seems to be riding on the tail end of global instability, with the potential for price normalization or further inflation depending on macroeconomic forces.

Types of Bitumen Available in Malaysia

Bitumen isn’t a one-size-fits-all product. Depending on the project and environmental conditions, different types of bitumen are used in Malaysia. Let’s break down the most common types found in the local market:

1. Penetration Grade Bitumen (e.g., 60/70, 80/100)

This is the most commonly used bitumen in road construction. The penetration grade refers to how deep a standard needle penetrates the bitumen sample under specific conditions. For Malaysia’s hot and humid climate, the 60/70 grade is preferred due to its ability to withstand higher temperatures without becoming too soft.

- Usage: Roads, pavements

- Price (2025): RM1,850–RM2,000 per MT

2. Polymer-Modified Bitumen (PMB)

PMBs are enhanced with polymers like SBS (styrene-butadiene-styrene) to offer superior elasticity, adhesion, and resistance to deformation. They’re essential for high-traffic highways and airport runways where performance matters most.

- Usage: Expressways, heavy-duty pavements, airports

- Price (2025): RM2,300–RM2,800 per MT

3. Oxidized Bitumen

Produced by blowing air through penetration grade bitumen, oxidized bitumen has better waterproofing and aging properties. It’s used more in industrial and roofing applications.

- Usage: Roofing, pipe coating, waterproofing

- Price (2025): RM2,000–RM2,500 per MT

4. Emulsion Bitumen

This is bitumen mixed with water and emulsifying agents. It’s used in surface dressing and maintenance works. While not as commonly discussed in pricing indexes, it’s increasingly popular for environmental reasons.

Knowing which type you need ensures not only better performance but cost-efficiency too. Always match the grade to your project requirements—overengineering can unnecessarily inflate costs, while underestimating can compromise durability.

Main Suppliers of Bitumen in Malaysia

The bitumen supply chain in Malaysia is a mix of local refiners, importers, and distributors. Here’s a look at some key players in the game:

1. Local Manufacturers

- Petronas: Malaysia’s national oil company supplies bitumen directly or through subsidiaries. Known for reliability and nationwide availability.

- Shell Malaysia: Offers high-quality bitumen, including polymer-modified variants. Widely used in premium infrastructure projects.

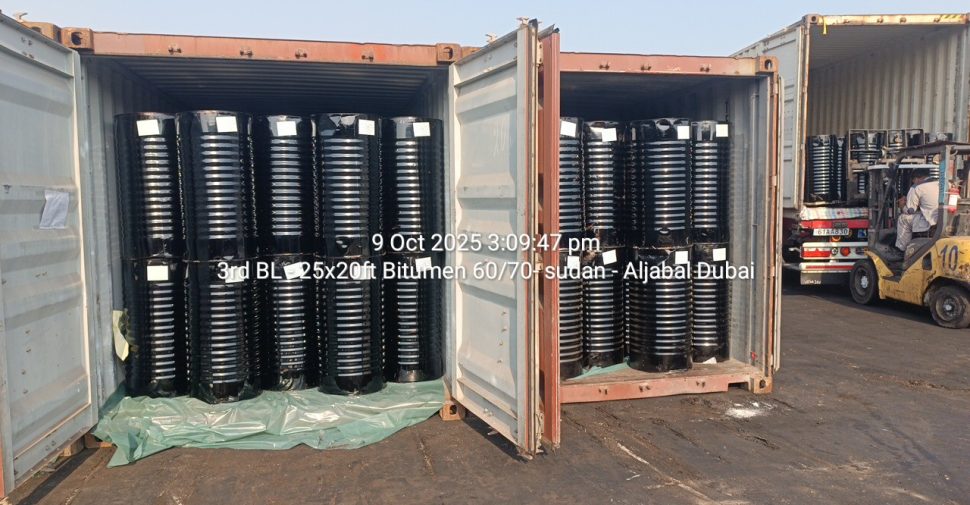

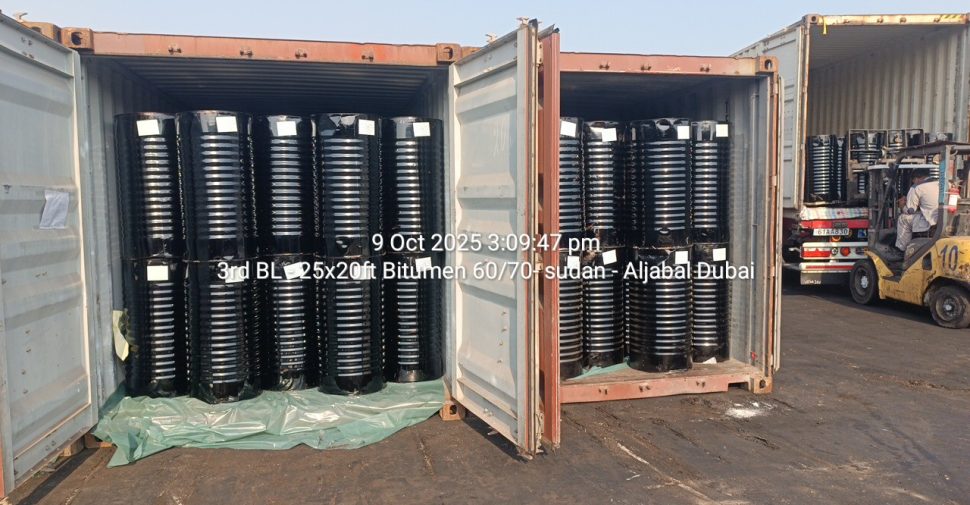

2. Importers

- Indian Suppliers: India is one of the largest exporters of bitumen to Malaysia. Companies like HPCL and IOCL export penetration and modified bitumen.

- Middle East Suppliers: UAE producers provide large volumes, especially of oxidized bitumen.

3. Distributors

Local distributors like Bitumas Asphalt, Hin Huat Bitumen, and Chin Wah (M) Corp act as intermediaries, offering flexible contracts, logistics support, and bulk purchase deals.

Whether you’re a government contractor or a private developer, choosing the right supplier is key. Price isn’t everything—consistency, timely delivery, and adherence to specifications are equally important. Many Malaysian projects now demand MS (Malaysian Standards) or ASTM compliance for procurement.

Bitumen Demand in Malaysia (2025 Overview)

Demand for bitumen in Malaysia is surging in 2025, driven by massive public and private infrastructure investments. The government’s continued focus on connectivity and urban development is a major growth engine.

Key Sectors Driving Demand:

- Highways and Roads: Under the 12th Malaysia Plan, highway expansion remains a priority. Projects like the Pan Borneo Highway and the Central Spine Road are ongoing.

- Airports: Upgrades to KLIA and regional airports require premium bitumen grades.

- Urban Development: New townships, industrial parks, and transport hubs demand high-quality road surfaces and waterproofing.

Budget Allocation for Infrastructure (2025):

- RM100 billion allocated to infrastructure in Budget 2025

- RM45 billion specifically earmarked for roads and transport

The demand breakdown by sector looks roughly like this:

| Sector | Bitumen Usage (%) |

|---|---|

| Roads and Highways | 65% |

| Airports | 15% |

| Real Estate | 10% |

| Industrial/Other | 10% |

The consistent growth in bitumen demand has led suppliers to boost inventories and secure long-term import contracts, helping to stabilize supply despite global uncertainties.

Global Oil Prices and Their Impact on Bitumen

Let’s not forget the elephant in the room—crude oil. Since bitumen is derived from the distillation of crude oil, its price moves almost in tandem with global oil markets.

In 2025, Brent crude prices are hovering around USD 87/barrel, up from the 2024 average of USD 81. This increase is partly due to:

- Continued geopolitical tensions in the Middle East

- OPEC+ supply cuts

- Increased post-pandemic demand in Asia and Africa

So, what does this mean for Malaysia?

- Higher production costs: Refining costs for local producers increase

- Expensive imports: Bitumen priced in USD becomes costlier with a weaker Ringgit

- Volatile local pricing: Suppliers frequently update rates, often monthly

To hedge against this, some large contractors and government projects enter into forward contracts or secure fixed-price agreements.

Price Forecast for Bitumen in Malaysia (2025–2030)

Looking into the crystal ball, analysts forecast a moderate increase in bitumen prices through 2030, assuming steady oil prices and continued infrastructure growth.

Projected Average Prices:

| Year | Forecasted Avg Price (RM/MT) |

|---|---|

| 2025 | RM2,200 |

| 2026 | RM2,250 |

| 2027 | RM2,280 |

| 2028 | RM2,300 |

| 2029 | RM2,330 |

| 2030 | RM2,350 |

These forecasts consider:

- Inflation and currency effects

- Government policy support

- Demand from ASEAN regional markets

- Global oil market outlook

Although the upward trend is modest, even small changes can impact project budgets significantly when purchasing in bulk.

Government Policies Affecting Bitumen Prices

In Malaysia, government intervention has a strong influence on the construction industry—and that includes the bitumen market. From import duties to environmental regulations, multiple policies shape how much you’ll end up paying for a tonne of black gold.

Key Government Influences:

- Import Tariffs and Duties

- While Malaysia produces some of its bitumen locally, a significant volume is imported. Government-imposed import duties can raise the final cost. As of 2025, there’s a 5–10% tariff on certain bitumen grades from non-ASEAN countries.

- However, ASEAN trade agreements allow for lower or zero tariffs, making imports from neighboring countries more competitive.

- Taxation Policies

- Bitumen is subject to Sales and Service Tax (SST), which affects procurement costs. There’s no specific subsidy on bitumen, unlike some fuels, so the end-users bear the full tax burden.

- Environmental Compliance Costs

- Regulations from DOE (Department of Environment) require bitumen storage and transportation to meet strict safety and environmental criteria. Compliance means extra costs for suppliers, which trickle down to customers.

- Budget Allocations

- Federal infrastructure funding indirectly affects bitumen prices. When the government announces major projects, demand spikes—and so do prices. The Budget 2025 allocation of RM100 billion for infrastructure has already caused a slight market surge.

- Price Control Considerations

- While bitumen is not price-controlled like diesel or RON95, there are murmurs in policy circles about capping prices for public sector procurement to manage national infrastructure costs.

Keeping up with policy shifts is crucial for forecasting costs accurately. Even a small change in tax law or tariff enforcement can make or break profit margins on large-scale projects.

Challenges in Bitumen Pricing in Malaysia

Despite growing demand and potential for profits, the bitumen industry in Malaysia faces multiple challenges that affect price stability and market confidence. Let’s take a closer look at the hurdles shaping the 2025 pricing scenario.

1. Supply Chain Disruptions

- Global logistics still haven’t fully recovered post-COVID and Ukraine war.

- Port congestion, container shortages, and delays at customs have led to delivery delays and inventory build-up costs.

- The situation worsens during monsoon seasons when transportation is naturally hampered.

2. Volatile Crude Oil Prices

- As bitumen prices are directly linked to crude, even minor fluctuations in oil markets cause chain reactions.

- In 2025, uncertainties around OPEC+ cuts and geopolitical tensions have created high market volatility.

3. Weakening Malaysian Ringgit

- The RM has seen periodic weakening against the USD, increasing the cost of imported bitumen significantly.

- As of October 2025, RM1 = USD 0.21, down from 0.24 a year ago.

4. Lack of Long-Term Pricing Contracts

- Most suppliers still rely on short-term pricing models (monthly or quarterly). This leads to unpredictable budgeting for contractors, who may suffer losses on long-term projects.

5. Environmental Regulations

- New sustainability regulations have made it more expensive to transport and store bitumen, especially in urban areas.

Overcoming these challenges requires a mix of strategic sourcing, government support, and smart contract structuring.

Opportunities for Investors in the Bitumen Market

While the challenges are real, so are the opportunities. The bitumen market in Malaysia in 2025 is buzzing with potential for local and foreign investors.

Why You Should Consider Investing:

- Massive Government Spending

- With a record RM100 billion infrastructure allocation in Budget 2025, there’s a massive demand pipeline for bitumen.

- Growing Export Potential

- Malaysia can become a hub for Southeast Asian bitumen exports. Investors can look at bulk storage facilities, repackaging, and resale in ASEAN.

- Innovation in Modified Bitumen

- The demand for polymer-modified and rubberized bitumen is growing fast. Setting up manufacturing or blending units could yield strong ROI.

- Logistics and Distribution Ventures

- Companies with efficient supply chains are in high demand. Investors can look at bitumen trucking fleets, port depots, or joint ventures with local distributors.

- Green Technologies

- With ESG (Environmental, Social, and Governance) gaining traction, bitumen recycling plants and emulsion tech can offer niche but profitable opportunities.

Bitumen isn’t just a commodity; it’s a strategic material. Smart investors with an eye on infrastructure can find golden opportunities in this sticky black business.

How to Buy Bitumen in Malaysia: A Guide

If you’re planning to procure bitumen in 2025, here’s a step-by-step breakdown to help you make smart, cost-effective decisions:

1. Choose the Right Grade

- Match your project specifications with the correct bitumen type.

- For highways: Use 60/70 penetration or PMB.

- For waterproofing: Go with oxidized or emulsion bitumen.

2. Decide on Quantity

- Bulk buying (over 20 MT) is more cost-effective and allows negotiation.

- Retail or small-scale purchases are priced higher and often come with extra logistic costs.

3. Vet the Supplier

- Check for certifications (MS, ASTM, ISO).

- Ask for recent test reports, especially for polymer-modified or oxidized types.

- Verify logistics capabilities—some suppliers offer end-to-end transport.

4. Understand Delivery Terms

- Bitumen is usually sold FOB (Free on Board) or CIF (Cost, Insurance, and Freight).

- Confirm who’s handling customs, unloading, and inland transport.

5. Secure a Price Lock

- If you’re working on a long-term project, negotiate fixed-price contracts or use price hedging strategies to avoid fluctuations.

A little preparation goes a long way in saving costs and avoiding delays.

Environmental Impact and Sustainability of Bitumen

Let’s not forget the environmental side of bitumen. While it’s indispensable, it’s also petroleum-based—raising concerns around emissions, waste, and non-renewability.

Major Environmental Concerns:

- Greenhouse Gas Emissions during manufacturing

- Urban Air Pollution from fumes during application

- Non-biodegradable Waste from old pavement layers

Sustainable Practices Emerging in 2025:

- Bitumen Recycling (Reclaimed Asphalt Pavement – RAP)

- Reuse of milled asphalt from old roads.

- Saves cost and reduces landfill use.

- Widely adopted in projects like Lebuhraya Pantai Timur (LPT).

- Warm Mix Asphalt

- Reduces mixing temperature, thus saving energy and lowering emissions.

- Being introduced in major urban developments.

- Bio-based Binders

- Innovations in using pine resin and vegetable oils as partial substitutes.

- Still in experimental phases but show long-term promise.

- Regulations

- Malaysia’s DOE now enforces stricter rules on bitumen storage, spillage control, and fume emissions.

Contractors and manufacturers who embrace sustainable practices early stand to benefit from future tax credits, incentives, and growing green project requirements.

Expert Opinions on Malaysia’s Bitumen Industry

Let’s hear what the industry insiders are saying about the bitumen landscape in 2025:

Dato’ Zainal, CEO of a Leading Construction Firm

“Bitumen pricing is a challenge, yes—but we’ve learned to mitigate risks through long-term supply contracts and working with multiple vendors. Planning is everything.”

Ir. Lim Wei Hoong, Civil Engineer & Infrastructure Consultant

“The shift to polymer-modified bitumen has significantly improved road quality. However, we need better regulations to prevent subpar imports from entering the market.”

Nurul Shafiqa, Energy Analyst

“Bitumen is more than just a road material—it’s part of the broader oil economy. As crude oil stabilizes post-pandemic, I expect moderate price growth through 2030.”

The consensus is clear: while challenges exist, Malaysia’s bitumen industry is robust, evolving, and full of opportunity for those ready to innovate and adapt.

Conclusion

Bitumen is a core building block in Malaysia’s infrastructure growth, and its price in 2025 reflects a perfect storm of global oil dynamics, local demand, and government policy. Whether you’re a contractor looking to quote your next tender or an investor considering the market, understanding the trends and forecasts is non-negotiable.

From types and suppliers to sustainability and future pricing, this guide has covered every aspect you need to stay ahead. As Malaysia continues to pave its way toward a high-income future, bitumen will remain at the heart of that journey—one tonne at a time.

FAQs

1. What is the current price of bitumen in Malaysia in 2025?

The average price ranges from RM1,850 to RM2,300 per metric tonne, depending on grade and supplier.

2. What factors influence bitumen prices in Malaysia?

Key factors include crude oil prices, import duties, currency exchange rates, demand from infrastructure projects, and supply chain conditions.

3. Who are the top bitumen suppliers in Malaysia?

Top suppliers include Petronas, Shell, and importers from India and the Middle East, along with local distributors like Bitumas and Chin Wah.

4. Is recycled bitumen used in Malaysia?

Yes, Reclaimed Asphalt Pavement (RAP) is increasingly used in road resurfacing projects to reduce costs and environmental impact.

5. How can contractors mitigate bitumen price volatility?

Contractors can secure long-term supply contracts, use price hedging strategies, or bulk-purchase during off-peak seasons.